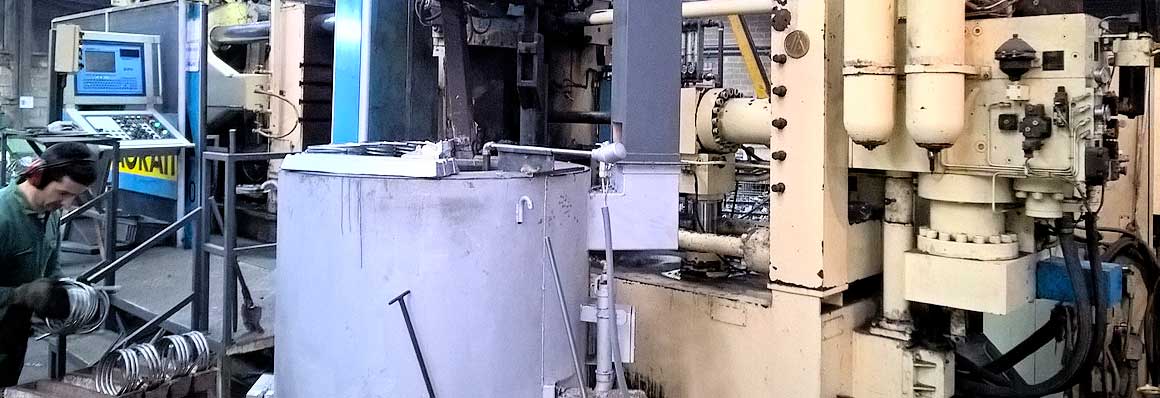

The machines and equipment

Injection presses

- 100 ton press

- 250 ton press

- 350 ton press

- 450 ton press

- 630 ton press

- 900 ton press

- Each fusion furnace is equipped with a thermocontrol system with recorder

Other equipment

- Installations of gravity die casting in permanent mould

- Completion Workshop

- Checkpoint / packing

- Computerised management

- Traceability guaranteed 10 years minimum

The team

- 1 workshop manager

- 1 maintenance manager

- 6 press operators

- 5 control completion operators

- 1 administrative and financial director

- 1 Design office / Quality manager

Design capacity

Coaching for the design of the piece, mould and cutting tools, in partnership with the mould makers maximizing the process. Realisation of prototype for the final validation by the client.

Certifications

ISO 9001

Certifications pending : ISO 9100

Our expertise

Production of pieces in injected aluminium,

or gravity die casting in permanent mould.